Metal Jacketed gaskets

Metal Jacketed gaskets

Metal Jacketed gaskets are available in standard or customized dimensions for heat exchangers or pressure vessels.

They are composed of a metal jacket and a soft filler.

Jacketed materials

SS 304L / SS 316L / SS 321 / SS 430 / Soft Iron / Duplex alloy / Copper / Brass / Aluminium / Titanium / Nickel / Nickel alloys

Shapes available

Oblong, rectangular, oval, diamond shapes are also available.

Standard dimensions according to:

DIN flanges, ASME flanges

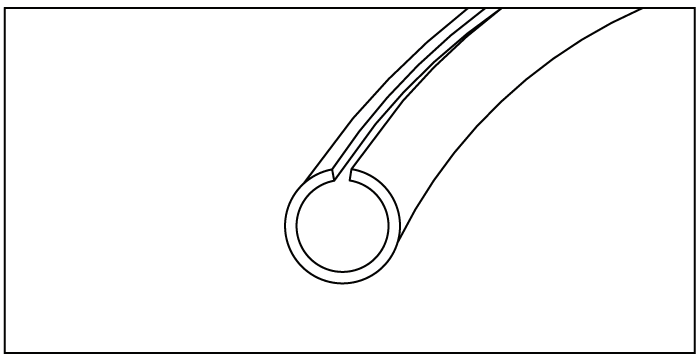

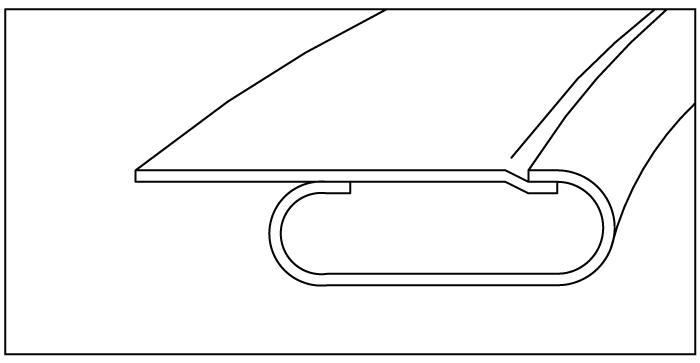

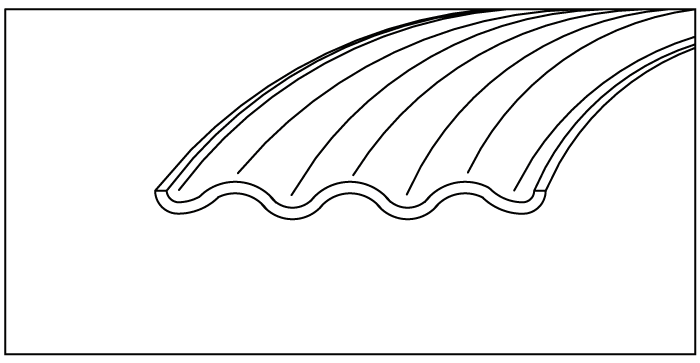

Single jacketed gaskets: they are used for relatively narrow applications. Made by encasing a soft filler on one face and both edges with metal.

Single jacketed gaskets: they are used for relatively narrow applications. Made by encasing a soft filler on one face and both edges with metal.

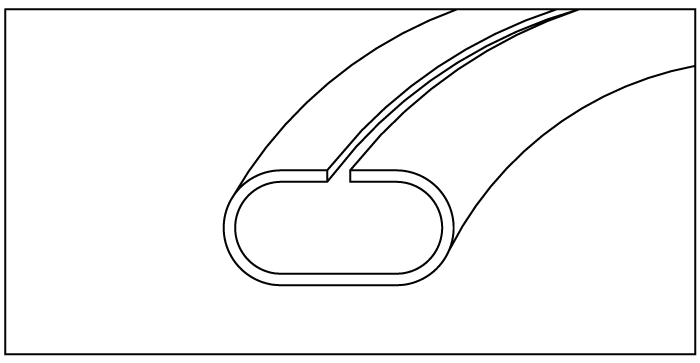

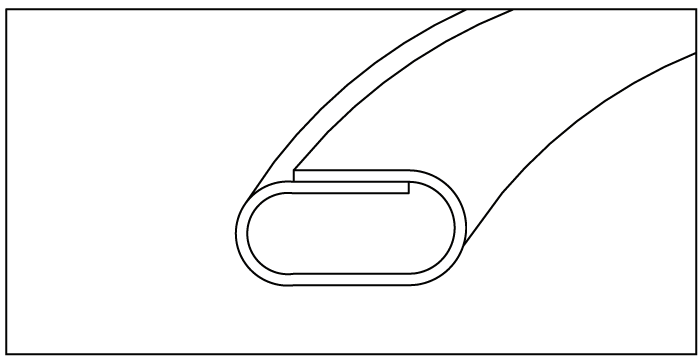

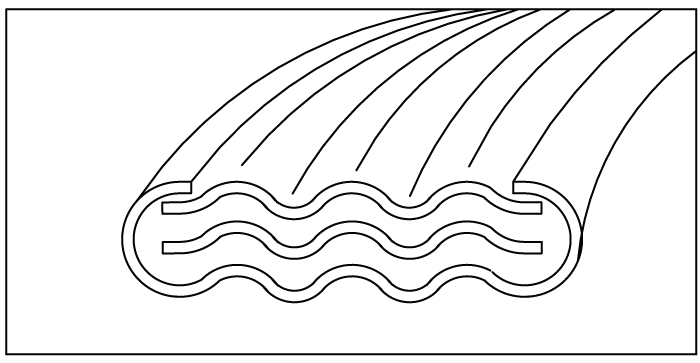

Double jacketed gaskets: they are used when complete protection of the filler is required. They also provide additional support of the flanges at the outer edges thanks to an overlapped jacket. They are made of a soft filler completely enclosed by a metal shell and a top washer.

Double jacketed gaskets: they are used when complete protection of the filler is required. They also provide additional support of the flanges at the outer edges thanks to an overlapped jacket. They are made of a soft filler completely enclosed by a metal shell and a top washer.

Double jacketed gaskets: they are used when complete protection of the filler is required. They also provide additional support of the flanges at the outer edges thanks to an overlapped jacket. They are made of a soft filler completely enclosed by a metal shell and a top washer.

Overlapped jacketed gaskets: they are used when a completely enclosed gasket is required whose width is smaller than the one available in the plain double jacketed series.

Double shell, double jacketed gaskets: they are used when a gasket having greater strength and rigidity is required. They are made of a soft filler by two reversed and overlapping metal shells.

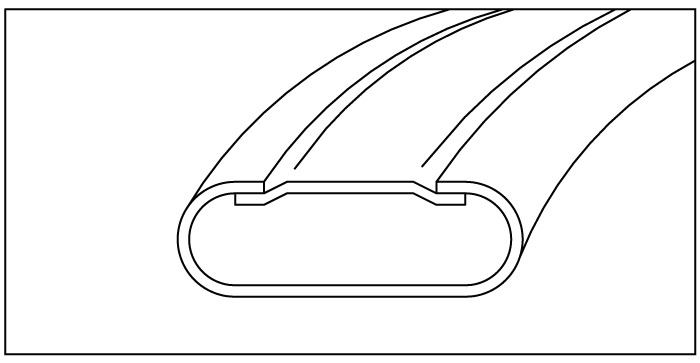

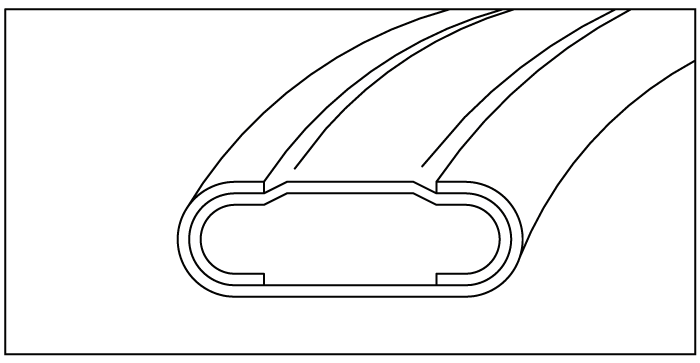

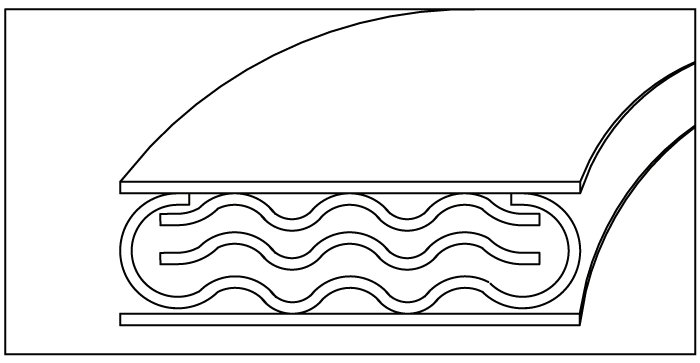

Corrugated jacketed gaskets: the corrugated jacketed increases the gasket resistance. This type employs an asbestos-free filler completely enclosed by a corrugated metal shell and a top washer. If a slight leakage occurs through the inner edge, the concentric corrugations act as labyrinth seal.

Corrugated jacketed gaskets: the corrugated jacketed increases the gasket resistance. This type employs an asbestos-free filler completely enclosed by a corrugated metal shell and a top washer. If a slight leakage occurs through the inner edge, the concentric corrugations act as labyrinth seal.

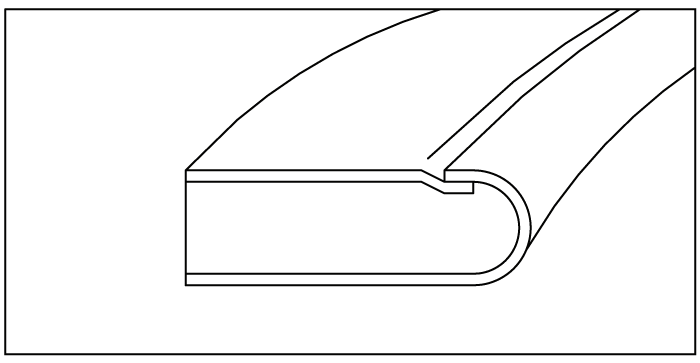

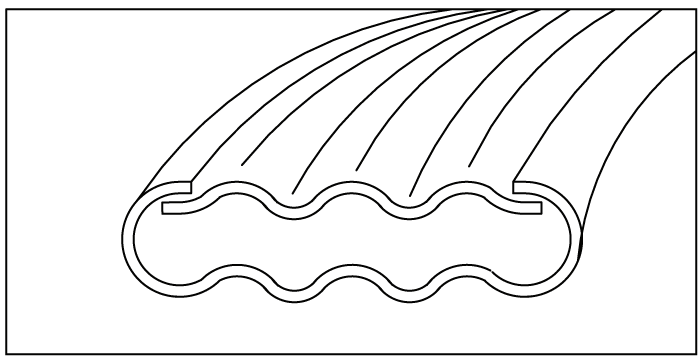

Corrugated jacketed gaskets with corrugated metal insert: like corrugated jacketed type with a corrugated metal insert. This 3-ply design provides a more resistant construction that adapts to cyclicle operating temperature problems.

Corrugated jacketed gaskets with corrugated metal insert: like corrugated jacketed type with a corrugated metal insert. This 3-ply design provides a more resistant construction that adapts to cyclicle operating temperature problems.