Weld ring gaskets

Weld ring gaskets

Weld ring gaskets are available in standard or customized dimensions for heat exchangers or pressure vessels. We can supply them with diameters up to 5000 mm and we can use the most particular materials, such as nickel alloys or duplex. Herunder are some examples of the possible materials and shapes available. Furthermore we can provide our customers with standard weld ring gaskets.

Weld ring materials

SS 304L / SS 316L / SS 321 / SS 430 / Soft iron / Duplex alloy / Titanium / Nickel alloys

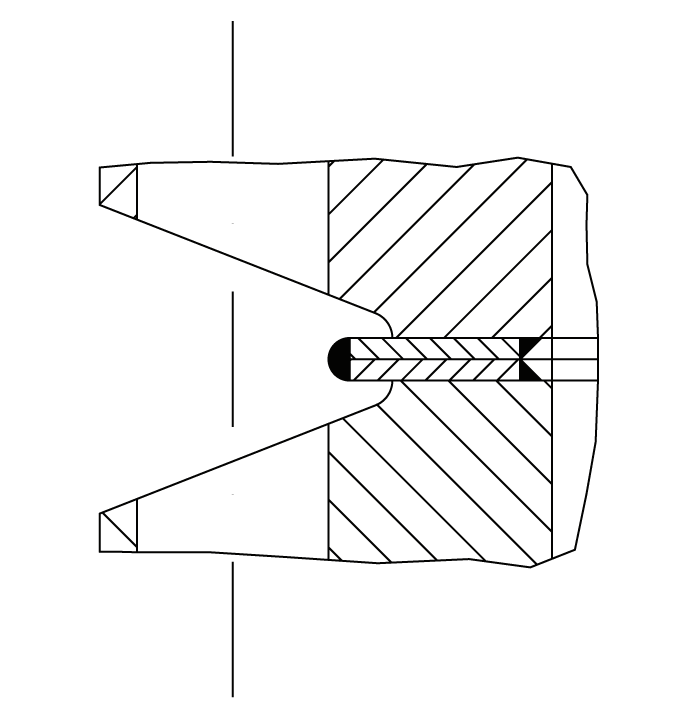

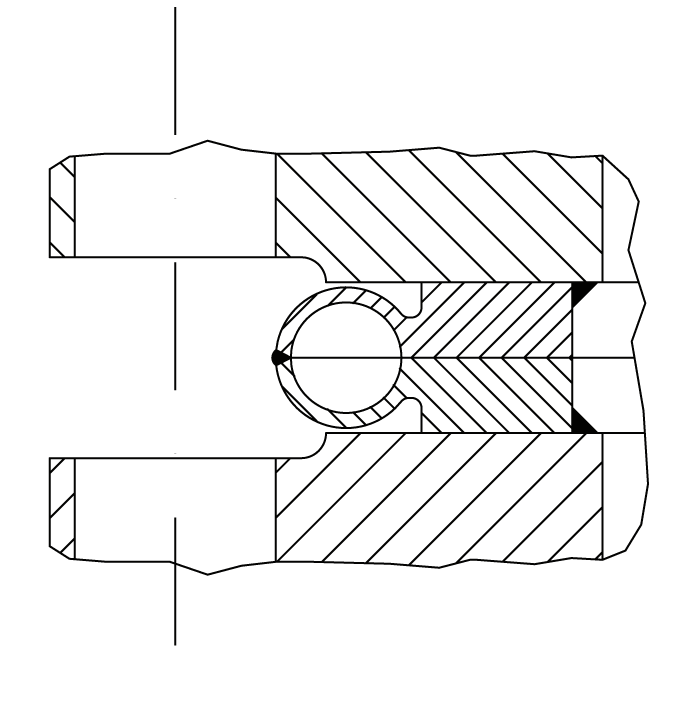

Membrane type - It is the easiest type to manufacture as to material and construction costs. It is especially used when the fitting space is reduced. Welds on the inside only are possible, unless an M flange according to DIN 2526 is fitted. Dismantling and re-welding are also possible.

This type of weld ring gasket does not prevent crevice corrosion to occur. Post-welding dismantling and re-welding are possible.

The same as WR01. Post-welding dismantling and re-welding are hardly possible.

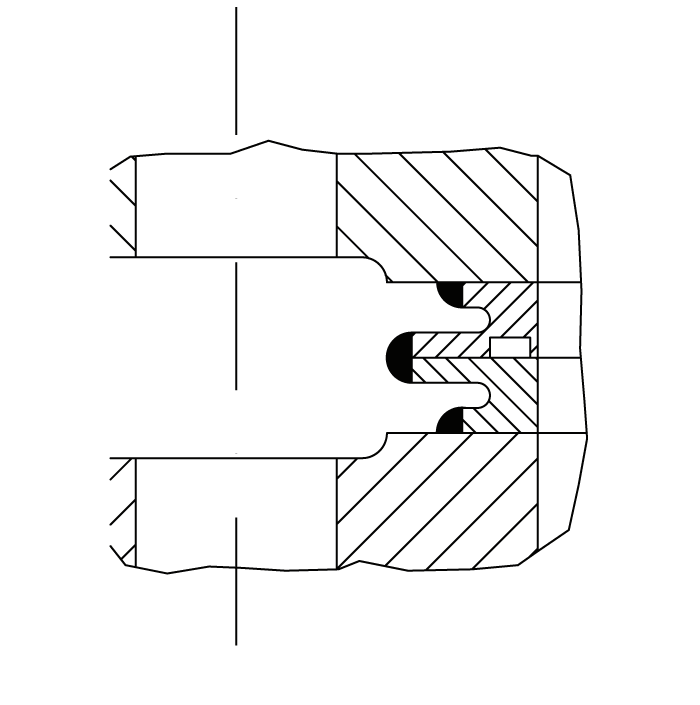

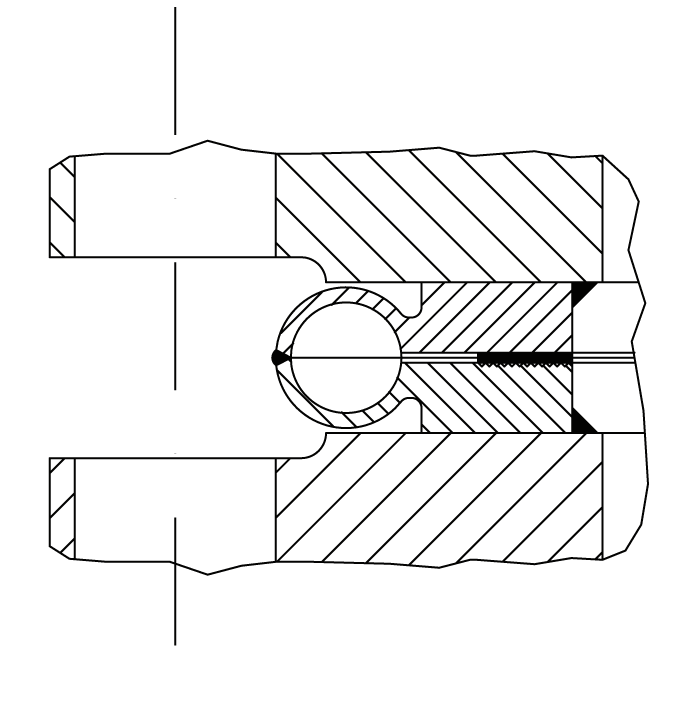

Welds on the inside can be possibly executed as additional fastening and only if continuously welded. Post-welding dismantling and re-welding are possible only as shown in the picture by means of a 2 mm cutting-off wheel.

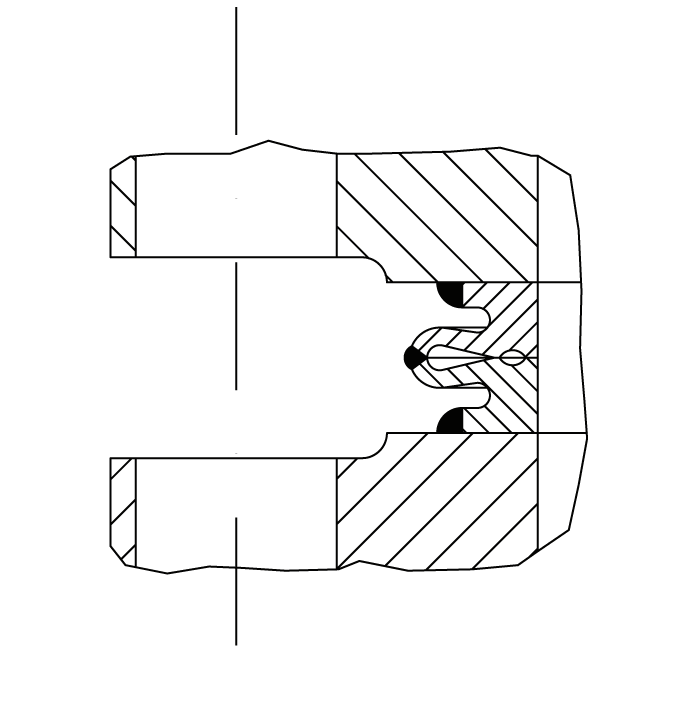

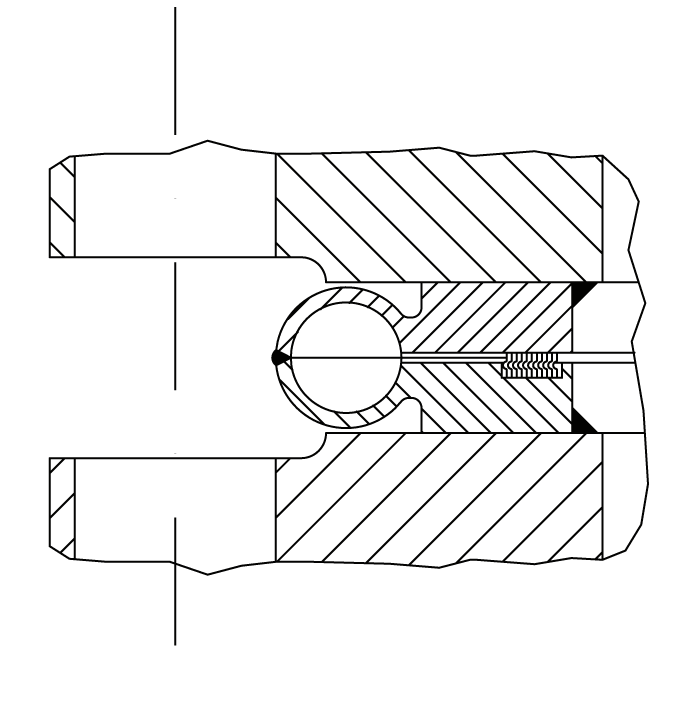

Welds on the inside are to be executed as shown in the picture so as to avoid crevice corrosion, whereas external welds are not possible. This type of weld ring gasket allows dismantling and re-welding with a 2 mm cutting-off wheel.

The auxiliary sealing is made directly on one of the weld ring gasket halves.

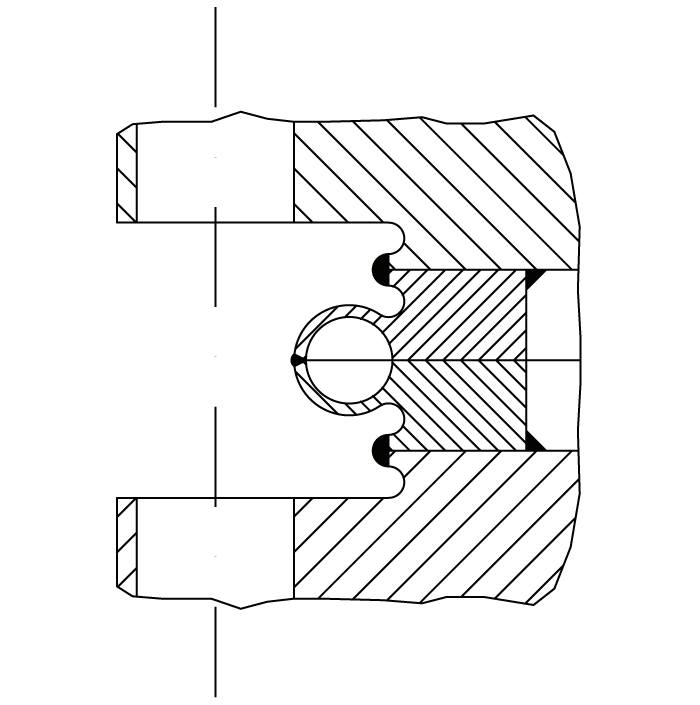

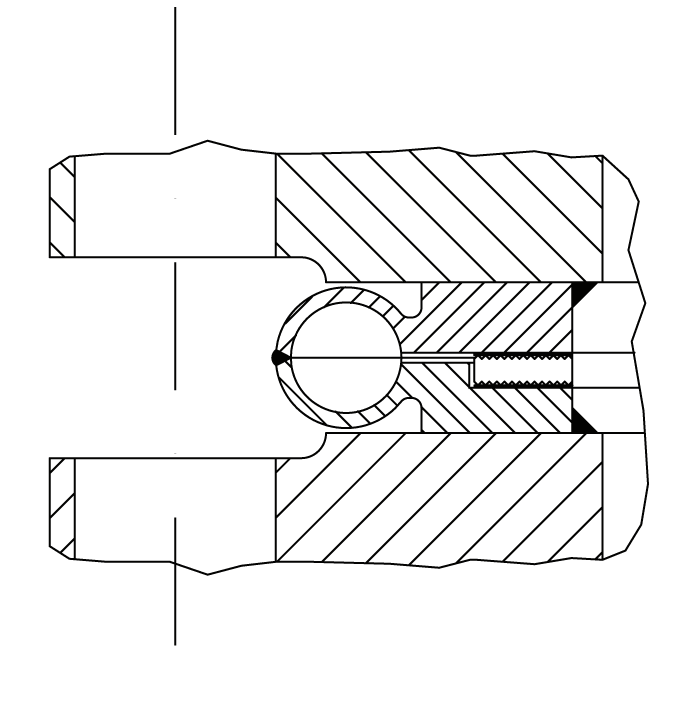

An auxiliary spiral wound gasket is fitted inside the weld ring gasket.

An auxiliary kammprofile gasket is fitted inside the weld ring gasket.